Shinohara UNO 52 offset press takes Print 05 by storm

The revolutionary UNO push-button small offset press from Shinohara was the focus of intense interest at last week's Print05 in Chicago. First displayed at IGAS two years ago, the single cylinder press represents the future of small offset, according to Bernie Robinson, general manager Currie & Company, the Shinohara agent in Australia.

The revolutionary UNO push-button small offset press from Shinohara was the focus of intense interest at last week's Print05 in Chicago. First displayed at IGAS two years ago, the single cylinder press represents the future of small offset, according to Bernie Robinson, general manager Currie & Company, the Shinohara agent in Australia.

"For me it was definitely the hit of the show. With its small footprint and the ability to print on a wide variety of stocks, including cardboard, with offset quality it represents a major advance for small to medium-size printers,” he said. "It is a fast change-over machine built to deliver short run printing."

The UNO is the latest in the range of Shinohara presses that cover the spectrum in size and configurations. From a normally configured 52 (370 x 520), through to a 66 (508 x 660), 75 (520 x 750) and 79 (600 x 790), Shinohara provides from two- to eight colour presses in high-, mid-, and low-pile versions for most sizes. One of Australia’s most popular press brands Shinohara has long been recognised as a technology benchmark setter.

With its own developed S-NET workflow system, Shinohara provides printers with state of the art integrated technology. It was one of the earliest members of the CIP 3 (now CIP4) international communication standards group. TheShinohara CIP3Station is one of the most sophisticated press control systems in the industry, while its Pre-Inking System (SPIS) dramatically reduces the press make-ready time for quick change over jobs.

With its own developed S-NET workflow system, Shinohara provides printers with state of the art integrated technology. It was one of the earliest members of the CIP 3 (now CIP4) international communication standards group. TheShinohara CIP3Station is one of the most sophisticated press control systems in the industry, while its Pre-Inking System (SPIS) dramatically reduces the press make-ready time for quick change over jobs.

The Shinohara Color Control Station (SCCS) is at the heart of a closed-loop system that helps to ensure consistent colour densities over the course of a print run. To prevent unnecessary colour shifting, a colour control bar on the target proof is scanned before the start of print job and used as a standard against which to compare colour density throughout the run.

In-line coating is the key

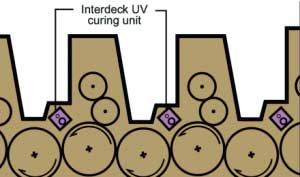

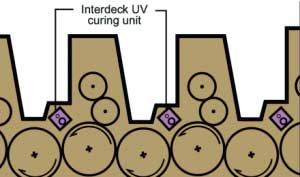

According to Robinson, Print05 was buzzing with the industry’s re-discovery of in-line coating. Many presses from different manufacturers displayed inline coaters including Shinohara, which had a six-colour press with cold UV interdeck driers and a UV coating unit at the end. “A very impressive piece of equipment with all the latest control features. Designed for niche packaging printers it is very productive,” he said.

The Shinohara interdeck UV curing system (pictured) reduces problems with trapping when UV/hybrid inks are used. Since Shinohara presses utilize cold UV drying, they can also be used for special types of production, such as printing onto plastic.

The Shinohara interdeck UV curing system (pictured) reduces problems with trapping when UV/hybrid inks are used. Since Shinohara presses utilize cold UV drying, they can also be used for special types of production, such as printing onto plastic.

Shinohara's in-line coating unit uses a chamber-type doctor blade system. The doctor blade creates an even layer of varnish on the sheet, assuring high-quality coating. The unit also features an automatic preparation unit and automatic washing, turning operations that used to be extremely time-consuming into simple touch-panel procedures that save time and trouble (wash time: about six minutes). The entire surface of the sheet can be coated, or spot coating can be used with the application of a convex resin plate.

The revolutionary UNO push-button small offset press from Shinohara was the focus of intense interest at last week's Print05 in Chicago. First displayed at IGAS two years ago, the single cylinder press represents the future of small offset, according to Bernie Robinson, general manager Currie & Company, the Shinohara agent in Australia.

The revolutionary UNO push-button small offset press from Shinohara was the focus of intense interest at last week's Print05 in Chicago. First displayed at IGAS two years ago, the single cylinder press represents the future of small offset, according to Bernie Robinson, general manager Currie & Company, the Shinohara agent in Australia.  With its own developed S-NET workflow system, Shinohara provides printers with state of the art integrated technology. It was one of the earliest members of the CIP 3 (now CIP4) international communication standards group. TheShinohara CIP3Station is one of the most sophisticated press control systems in the industry, while its Pre-Inking System (SPIS) dramatically reduces the press make-ready time for quick change over jobs.

With its own developed S-NET workflow system, Shinohara provides printers with state of the art integrated technology. It was one of the earliest members of the CIP 3 (now CIP4) international communication standards group. TheShinohara CIP3Station is one of the most sophisticated press control systems in the industry, while its Pre-Inking System (SPIS) dramatically reduces the press make-ready time for quick change over jobs. The Shinohara interdeck UV curing system (pictured) reduces problems with trapping when UV/hybrid inks are used. Since Shinohara presses utilize cold UV drying, they can also be used for special types of production, such as printing onto plastic.

The Shinohara interdeck UV curing system (pictured) reduces problems with trapping when UV/hybrid inks are used. Since Shinohara presses utilize cold UV drying, they can also be used for special types of production, such as printing onto plastic.